Blacksmithing

and Cutlery

by Gérard HEUTTE

|

|

Steel grain

Steel grain

|

Bases

Steel is not a homogeneous matter! The page on

microstructure

already gives an outline.

Steel is not a homogeneous matter! The page on

microstructure

already gives an outline.

Moreover, steel consists of juxtaposed grains. Each

grain can contain one or more components, in the form of plates, of

needles or pearls...

The structure inside a grain is in general rather

regular. The border between two grains is called "grain

boundary". It can be a simple change of orientation of the

crystal matrix or a space containing one or more phases of steel,

such as for example Cementite. See the opposite diagram.

For example, a hypereutectoid steel with 1% Carbon will have

grains of Pearlite (containing 0.77% of Carbon) and grain

boundaries with Cementite. Broadly the proportion of Carbon is

1% well. But on a macroscopic scale, the uniformity does not

exist! ! !

Why be worried about?

Why be worried about?

The grain size has a major influence on the

mechanical properties of steel in term of strength and cutting ability!

A good blade must have a fine grain.

Theoretical definition of the grain size

Theoretical definition of the grain size

French reference: NF IN ISO 643 standard

Reference the USA: ASTM

| N° |

Average diameter (µ) |

General appreciation |

| -1 or 00 |

500 |

Very coarse |

| 0 |

360 |

| 1 |

250 |

Coarse |

| 2 |

180 |

| 3 |

125 |

| 4 |

90 |

Average |

| 5 |

65 |

| 6 |

45 |

| 7 |

32 |

Fine |

| 8 |

22 |

| 9 |

16 |

| 10 |

11 |

Very fine |

| 11 |

8.0 |

| 12 |

5.6 |

| 13 |

4.0 |

Ultra fine |

| 14 |

2.8 |

| 15 |

2.0 |

But all this information is not usable easily!

In practical

In practical

To make sure that the size of grain of the

blades is correct, it is necessary to make tests!

Make a blade with your usual working method. Then break

it (by tightening it in a vice and strongly striking it with

a hammer). The grain can then be observed in the zone of

rupture. If you can see it with eyes, it is too coarse.

If you distinguish it a little with a magnifying lens, it is

already well (but can be better). If you do not see it

with a magnifying lens it is a very fine grain!

Grain size growth

Grain size growth

It is not a sought effect, but unfortunately frequent!

The grain tends to become bigger via two factors:

> High temperature.

> Long duration of heating.

Be careful, temperature is the critical parameter for grain growth! Time is a less

important parameter. A strong overheating has more impact than a blade kept in fire for a

few minutes.

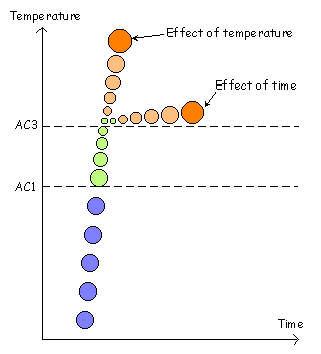

The opposite diagram shows clearly what occurs:

> The rise in temperature does not produce an effect on the

grain until AC1 (blue part).

> Between AC1 and AC3, the grain size decreases (green part)!

> If you continue to increase the temperature or if you

maintain long enough a temperature higher than AC3, the grain grows

bigger (pink and orange parts)...

> Any later cooling from there will left a coarse grain.

Grain size reduction

Grain size reduction

The size of the grain could be reduced by heat

treatment.

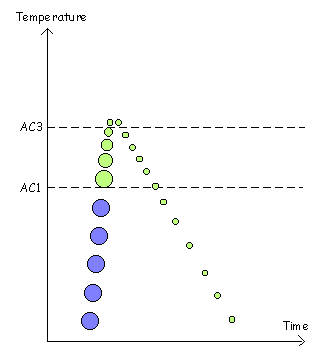

The figure opposite shows the principle:

> Go up in temperature a little above AC3 (blue part).

> Go down quickly below AC1, before the size of

grain increase (green part).

> As soon as the temperature passed below AC1, no more

risk of enlargement of the grain.

> Then you can heat the steel to start again this operation.

The whole set of these operations is called

Normalization.

| | |