Blacksmithing

and Cutlery

by Gérard HEUTTE

|

|

Make a U-shaped forge

Make a U-shaped forge

|

This article presents the realization of a do-it-yourself forge. Its shape out of U

makes it very practical to forge blades. The materials are

mainly of junk except a bit of refractory cement... The target

is to carry out an effective, portable and cheap construction.

The body is a part of a compressed air tank for truck. You can get one for free in the dustbins

of the garages for heavy lorries!

The tuyere is a simple drilled tube and placed at the bottom.

The inside of the hearth is made of refractory cement.

Principles

Principles

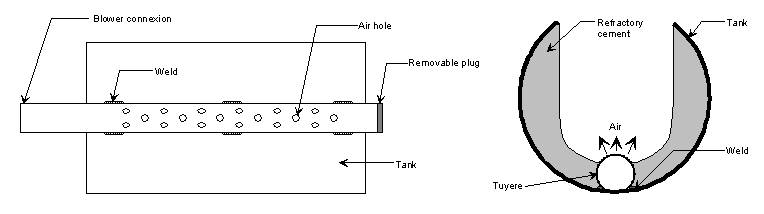

The two sketches below show the basic elements

for this realization.

On the left, a sight from top. To notice:

> The top of the tuyere is drilled with holes of 8 or 10, to diffuse

the air at the bottom of the hearth.

> The tuyere exceeds a little in front of the forge.

A removable plug will be placed here, which allows periodic

cleaning.

> The tuyere exceeds on the back of the forge (10cm).

You can connect here the tube coming from the blower.

The air circulation avoids an excessive heating.

> The tuyere is welded directly onto the bottom of the tank.

On the right, a cut showing:

> Diffusion of the air at the bottom of the hearth.

> The fitting conduit/refractory cement. The cement partially covers the

tuyere but leaves the holes apparent.

The approximative size of this forge is:

> Tank diameter 250mm

> Total lenght 480mm

> Fire earth useful lenght 370mm

> Fire earth width 160mm

> Fire earth height 170mm (from the top of the tuyere to the top of the forge)

> Front and rear bricks height 55mm (from the top of the tuyere to the top of the bricks)

Steps of the realization

Steps of the realization

1 - Prepare the tank by cutting the

two ends and the top. For practical questions, it will be

necessary to weld a base for stability. Four blocked

squares are used to put feet when a support is not available.

Since the initial version, I have drilled each of these squares and

the feet to be able to link via a bolt.

1 - Prepare the tank by cutting the

two ends and the top. For practical questions, it will be

necessary to weld a base for stability. Four blocked

squares are used to put feet when a support is not available.

Since the initial version, I have drilled each of these squares and

the feet to be able to link via a bolt.

2 - The conduit is a metal tube (construction steel E24)

of 40mm diameter. Drill the tube with a series of holes

(diameter 8 or 10). Then weld this tuyere on the bottom

of the tank.

3 - Then, the refractory cement should be put.

This operation is made in three steps. First

of all, the bottom then each side by laying down the bottle

on the side. The front and the back are "closed" by bricks.

3 - Then, the refractory cement should be put.

This operation is made in three steps. First

of all, the bottom then each side by laying down the bottle

on the side. The front and the back are "closed" by bricks.

On the photograph opposite, the coating with the

refractory cement on one of the sides. The

forge is lying on the side, the ends are temporarily blocked by

two refractory bricks. Then, the cement then is put in the

area thus delimited...

4 - Let dry a few weeks. For the

startup, make increasingly hot fires, to "cook" the refractory

cement. Opposite, the forge under operation (1) from face

(2) from profile below. To note, the telescopic system to support

the part during heating.

The forge is posed here on a junk frame.

Some tricks and ideas

Some tricks and ideas

To dimension the size of the hearth easily, the

simplest means is to place a brick or a brick back at the rear of the

hearth, directly posed on the conduit... Thus, the distance between the part and the

tuyere will be correct.

A support for rod can be carried out with two tubes

welded along the tank. These two tubes receive then a

sliding support, made out of concrete-reinforcing steel (folded and

welded).

Some improvements are possible. First of all, side handles to facilitate the displacement

of this forge.

You can also add a removable cap (in form of vault) out of

refractory material. This cap facilitates the rise in

temperature of the forge.

Among the limitations, the main one is impossibility of

using borax. Indeed, this one would fall at the bottom of the

forge and would end up destroying the tuyere. A side

tuyere would make it possible, but it is

another history...

| | |