Blacksmithing

and Cutlery

by Gérard HEUTTE

|

|

Making of a knife with hidden tang

Making of a knife with hidden tang

|

Here is, step by step, the assembly process for a knife with hidden tang.

There are probably some other ways of making. This

method does not require too much specialized tools.

The sketches show the parts of profile, with possibly the

corresponding sections (hachured).

I will place photographs as soon as possible...

Basic recall and vocabulary

Basic recall and vocabulary

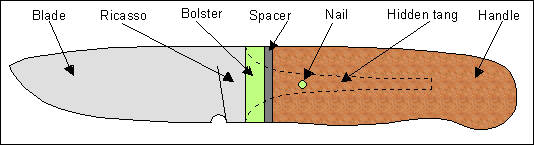

Here is what a knife with hidden tang looks like:

The tang goes through the handle, dug beforehand. The assembly

is made by gluing and/or a nail which crosses the handle and the tang.

You can replace the bolster by a guard if you wish to protect

the fingers from the edge, if ever the knife suddenly slip into

the hand.

Blade

Blade

It is necessary to make or get an adequate blade, like this one:

How to forge a

blade with hidden tang.

Bolster and spacer

Bolster and spacer

Start from a brass or better nickel silver flat part:

- Width: Thickness of the knife + margin.

- Length: Height of the knife (or the guard) + margin.

- Thickness: A few millimetres at least.

Measure the section of tang behind the ricasso and at a

distance corresponding to the thickness of the bolster. Transfer

the form on the flat part. Make the rectangular hole (some

holes inside the shape then work with the file.

Bevel the small side to be enable the bolster to come

in contact with the ricasso. Work very

gradually to avoid a gap at the junction

ricasso/bolster.

For the spacer, you can choose a reconstituted wood coloured

(see at Mercorne

) or leather.

Cut out with a cutter a rectangular hole to be able to

pile up the spacer on the bolster.

From the left to the right: From the left to the right:

- Holes in the flat part.

- Bolster with rectangular hole.

- Bolster seen of profile. The hole was bevelled to adapt

to the tang.

- Spacer seen of profile.

Handle

Handle

1 - First of all, it is necessary to drill

the piece of wood in the axis. For that, you can drill a hole

as a guidance at each end. The hole of bottom will be inserted in an

ankle itself placed in a wooden support, in the axis of the drill.

Drill through the second hole until the desired length.

1 - First of all, it is necessary to drill

the piece of wood in the axis. For that, you can drill a hole

as a guidance at each end. The hole of bottom will be inserted in an

ankle itself placed in a wooden support, in the axis of the drill.

Drill through the second hole until the desired length.

2 - The entry should now be widened. For that drill two

slanting small holes, then enlarge them. The excess

matter can be removed with a wood chisel and/or a rasp.

2 - The entry should now be widened. For that drill two

slanting small holes, then enlarge them. The excess

matter can be removed with a wood chisel and/or a rasp.

Work by successive improvements while trying to

enter the tang in the handle.

For this work of fitting, it could be useful to modify a round

rasp with the angle grinder to give it a square section with teeth on

only one face. Be careful to not soften it.

Assembly and shaping

Assembly and shaping

1 - First, the parts should be

prepared. Surfaces which will be glued must be striped with a

coarse grit sandpaper. They must then be degreased (with

acetone for example). They must not be touched any

more.

2 - Prepare the glue. I use araldite with

two components. Avoid the glues with rapid hardening.

They do not allow any error and further it is necessary to make

quickly! You can add sawdust there coming from

material of the handle. This sawdust colors the glue and

makes possible to absorb dilations at the time of polymerization.

3 - Fix the blade in a vice with the tang upwards.

Coat the tang of glue.

4 - Whitewash of glue the hole in the bolster and

insert it on the tang (in the rigth way). Coat the visible part of the bolster with

glue. Thread the spacer on the tang and apply it on the

bolster. Coat the visible part of the spacer with glue.

Using a stem, fill the hole of the handle of glue.

Insert the handle on the tang.

Here is this stacking:

Do not worry about the glue overflow around the bolster, the spacer and the

handle... To remove the whole from the vice. Fix the

whole by the handle in the vice.

5 - The whole should be now tightened. For that

you can use a screw clamp on the blade, by protecting it by two clamps.

Use two other large screw clamps to compress the whole, by leaning

on the first clamp and the end of the handle!

The glue must "flowe" generously. Remove with a

solvent (in general alcohol) the surplus of glue around the

Bolster/Ricasso junction.

Let dry.

6 - It is now necessary to give a shape to the handle.

You can "squared initially". Regularize the

thickness of the handle, while taking care of his alignment with the

blade. Then, give to the handle the desired profile.

7 - Eliminate the surplus of matter beyond

the blue line of the final profile.

In the second time, one will break the angles to round the

shape.

All these operations will be done with an abrasive. The

ideal is the backstand. If as me you do not have one, it is

possible to use a drilling machine with abrasive discs (coarse grain).

For the completion, abrasive paper bands of increasing

fine grit give good results.

In option: The crossing nail

In option: The crossing nail

If you wish to reinforce the assembly, it is

possible to put a crossing nail.

The simplest method consists in making the assembly until you get

the handle squared. Then, fix the blade at horizontal and drill

the tang and the handle. To know where to drill, it is

necessary to envisage a template out of paperboard of the blade and the tang,

with the location of the hole, defered on the handle.

Prepare a nail (stem of brass or copper nickel from 2 to 4 mm

diameter) by striating it with the file to

facilitate the fixing of the glue. One of the ends will be

made slightly conical to facilitate the insertion. Insert

the nail whitewashed beforehand with glue.

| | |