Blacksmithing

and Cutlery

by Gérard HEUTTE

|

|

Blacksmithing exercices

Blacksmithing exercices

|

This page proposes blacksmithing exercises.

The objective is the learning of the elementary operations which

will allow by combining them to make a good blade.

Ideally, it is desirable to learn under the supervision of a

blacksmith. These indications will not replace a teacher,

when you have the chance to get one!

Of course, it is necessary to have a minimum of tools:

Forge and fuel, anvil or stack, hammer, tongs...

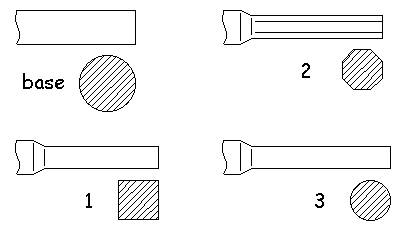

Principle of creep

Principle of creep

This is THE principle you must understand to be able to forge!

When you hit on the steel,

it loses thickness and the matter is pushed on the sides.

This effect is stronger when the surface of impact is curve

rather than flat. According to the shape of the hammer which

strikes, the matter can move according to a privileged axis:

With a circular impact, the matter is driven out

in a homogeneous way.

|

|

With a rectangular impact, the matter is more

strongly driven out along large sidess.

|

The thickness reduction also creates an alongement in the

axis of the most important deformation. The figure opposite

shows the part from profile before and after impact.

The thickness reduction also creates an alongement in the

axis of the most important deformation. The figure opposite

shows the part from profile before and after impact.

The reference marks (X) show well the increase length of the part.

Planing

Planing

When the hammer struck several times a part, the

surface quality of this one is presented in the form of a

juxtaposition of more or less regular hollows... It is then

necessary to plane the part to give it a good surface quality.

For that two methods:

When the hammer struck several times a part, the

surface quality of this one is presented in the form of a

juxtaposition of more or less regular hollows... It is then

necessary to plane the part to give it a good surface quality.

For that two methods:

- Set hammer. It

is a tool with a flat face which comes on the part. The part

is planed by striking on the top with the hammer. Move the set

hammer on all surface to work. The problem is that it is

necessary to be two to use a set hammer. Indeed, it is

necessary to hold the part, the set hammer and to strike with the hammer...

- Hammer.

A delicate and regular striking with the hammer makes

possible to arrive at the same result! It is just a little more

difficult and a little longer. It is the best way of making

when you work alone.

Stretching

Stretching

The stretching is a fundamental operation for blacksmithing.

It consists in lengthening a part while decreasing its

section. You can practise in two different ways:

The stretching is a fundamental operation for blacksmithing.

It consists in lengthening a part while decreasing its

section. You can practise in two different ways:

- On the anvil horn :

In this case, the creep is done by the lower part. It is the

convex part of horn which allows the crushing and the lengthening of the

metal. The figure on the left indicates the position of the bar

and the cross the zone of impact for the hammer.

- Hammer : You must use a convex hammer or one with a

narrow transversal peen (and of course convex).

The work is made on the table of the anvil

and the creep is done by the top.

In general, it is necessary to plane surfaces after the

stretching.

Very often, the blacksmith will combine these two

possibilities. He will work on the round horn and will

use a strongly convex hammer!

For stretchings on big lengths, it will be better to often

correct the resulting shape, by planing and rectifying it.

Flat part

Flat part

During this exercise, one will create a flat part

starting from a round. This simple exercise takes all its

interest if precise dimensions are wished. For example, to go

from a round of 10 to a flat part of 3x12.

During this exercise, one will create a flat part

starting from a round. This simple exercise takes all its

interest if precise dimensions are wished. For example, to go

from a round of 10 to a flat part of 3x12.

Crush strongly the bar to start to form the

rectangular section. Then, work on the edge to

complete the section. Then, work on all the faces for a

better regularity. Stretch to adjust dimensions. Rectify

the flat part regularly.

To supplement this exercise, it will be necessary to be

involved with:

- To decrease the width of a flat part by preserving the

thickness.

- To decrease the thickness while preserving the width.

Modification of section

Modification of section

During this exercise, you will modify a metal rod

to get a square, octagonal then round again.

During this exercise, you will modify a metal rod

to get a square, octagonal then round again.

Start this exercise over a small length

(10cm) before testing on bigger lengths.

(1) Square : Work on

the flat part of the anvil. It is necessary to crush the round

according to two orthogonal axes. If you hold the round with a

tong, you will work in general on two faces. If you hold the

round with the hand, it will be easier to work on the four faces.

In all the cases, it is necessary to work alternatively on the

two orthogonal axes.

Possible troubles:

- Angles rounded or bad surface quality. Several causes

are possible. Most probable is a bad "blow of hammer".

The peen is poorly controlled and does not strike all the time

the metal with the right orientation. Also take care of resting

the part on the flat of the anvil.

- Rhombus. The angle between the two axes does not make

90 degrees. It is the most difficult trouble to correct!

It is necessary to position the bar cantilever on the anvil and

to hit on the top to exert a kind of shearing (see sketch opposite).

It is often necessary to remake a finishing work after this kind

of correction.

- Rhombus. The angle between the two axes does not make

90 degrees. It is the most difficult trouble to correct!

It is necessary to position the bar cantilever on the anvil and

to hit on the top to exert a kind of shearing (see sketch opposite).

It is often necessary to remake a finishing work after this kind

of correction.

- Rectangular section. An axis was worked more than the

other. One can rectify easily by crushing the greatest width.

- Spin. This defect often occurs over the big lengths.

It translates a light defect of support of the part. You

can rectify the work progressively.

(2) Octagonal : The transformation of

the square in an octagon is done by "breaking" the four angles of

the square section. For that, place the square on the

anvil posed on an angle. Hit delicately on the

angle of the top. Break thus successively all the

angles. The difficulty is to proportion the octagon.

(3) Round : A return to a

round section is done by breaking all the angles of the octagonal

section... It will be necessary to avoid creating

surfaces. For that, one will make turn the bar on his axis at

the time of strike.

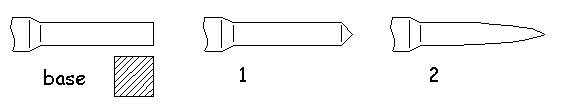

Curve a flat part

Curve a flat part

This exercise of preparation for the forge

of the blades is extremely simple. It is necessary to start

from a flat part and to give it a curve, without spin it and by

preserving the thickness. The sketch opposite is explicit.

Work alternatively:

This exercise of preparation for the forge

of the blades is extremely simple. It is necessary to start

from a flat part and to give it a curve, without spin it and by

preserving the thickness. The sketch opposite is explicit.

Work alternatively:

- On the anvil horn and the flat part of the side for the curve.

- On the flat part of the anvil to rectify the thickness.

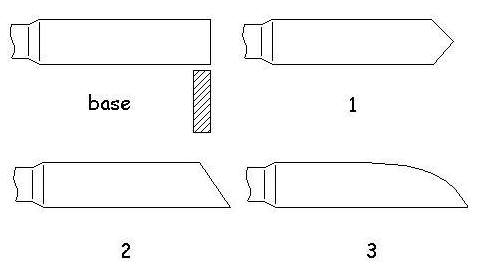

Point

Point

This exercise consists in making a point at the

end of a square. Start by creating a "pyramid" at the

end of the square. Then make "go up" the edge to

refine the point. You can continue until this edge disappears.

This exercise consists in making a point at the

end of a square. Start by creating a "pyramid" at the

end of the square. Then make "go up" the edge to

refine the point. You can continue until this edge disappears.

bevelled point

bevelled point

This exercise consists in forging a point in

bevel at the end of a flat part. Start by breaking the two angles. For that,

strike at the end at 45°. The thickness is often rectified.

This method avoids the formation of a lip or a fold which would

weaken the point. Folds back the angle thus formed.

Then Round the bevel if necessary...

This exercise consists in forging a point in

bevel at the end of a flat part. Start by breaking the two angles. For that,

strike at the end at 45°. The thickness is often rectified.

This method avoids the formation of a lip or a fold which would

weaken the point. Folds back the angle thus formed.

Then Round the bevel if necessary...

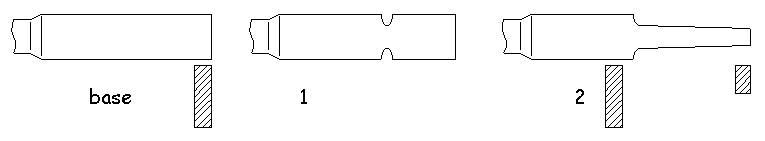

Simple leading edge

Simple leading edge

It is a question of carrying out a fast change

of section. The thickness of the flat part is kept but its

width decreases abruptly starting from a mark. It is the kind

of work used for the stem of blocking for Piedmontese or to forge a

spiral at the end of a handle in full-tang.

Initially, mark the leading edge in "A". For that,

you can use:

- Round anvil horn. It is suitable if you wish a soft or round

transition between the two sections. Attention,

the smallest "radius" of anvil horn is not so small!

Pose the edge of the flat on the horn and strike strongly by

the top to make a hollow.

- Edge of the anvil. One will place the flat part at

45°...

- Fuller. It is a specialized tool which fits in the

square hole of the anvil. It is the same principle that with

horn, but the ray is much weaker!

The excess part (on the right of "A" on the sketch) will be

then stretched. The final shape in "B" will depend on what was

used to mark the setback...

leading edge

leading edge

It is the operation which makes it possible to create a tang.

It is very close to the technique explained above.

Two marks should be made, while taking care of their alignment.

In the same way, the excess part will be stretched. In

the case of a tang, take care to create conicity in width and thickness.

And now, with these exercises, we have seen the bases necessary to forge blades.

And now, with these exercises, we have seen the bases necessary to forge blades.

| | |