Blacksmithing

and Cutlery

by Gérard HEUTTE

|

|

Steels used for cutlery

Steels used for cutlery

|

Many steels are available on the market. The

first work of the cutler will be to choose one of them! But do not

take one randomly. You need combine the required qualities

of the steel and the availability...

Here are some elements to make this choice.

Description of a steel

Description of a steel

At the time of the purchase of a steel, it is

necessary to get information to allow working it correctly.

It is only with these physical data that you will be able

to harden it correctly and make the right heat treatments.

This information is at least:

- Chemical composition

- Temperature of forging

- Temperature (and if possible methods) for annealing

- Temperature and medium for hardening

- Hardness after hardening

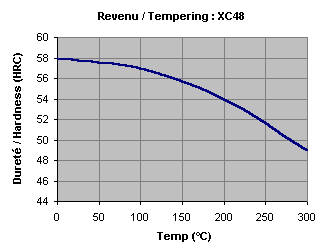

- Curve for the tempering (i.e. hardness according to the

temperature)

Steels for cutlery

Steels for cutlery

The following table presents some steels among the most current.

Chemical composition is provided in percentage of mass.

Classical

Designation |

US

Designation |

Numerical

Designation |

C |

Cr |

Mn |

Mo |

Ni |

Si |

V |

W |

Comment |

| XC48 |

±1045 |

- |

0.48 |

- |

0.55 |

- |

- |

0.25 |

- |

- |

Non-allied steel. A bit light in hardness. |

| XC75 |

±1078 |

- |

0.75 |

- |

0.55 |

- |

- |

0.25 |

- |

- |

Non-allied steel. |

| XC100 |

±1095 |

- |

1.00 |

- |

0.55 |

- |

- |

0.25 |

- |

- |

Non-allied steel. Hard. |

| XC130 |

- |

- |

1.30 |

- |

0.55 |

- |

- |

0.25 |

- |

- |

Non-allied steel. Very hard. |

| 135C3 |

- |

- |

1.35 |

- |

0.55 |

- |

- |

0.25 |

- |

- |

Equivalent XC130, but better hardenability. |

| 90MCV8 |

O2 |

1.2842 |

0.90 |

0.40 |

2.00 |

- |

- |

- |

0.10 |

- |

Tool steel. |

| 100C6 |

52100 = L3 |

- |

1.00 |

1.50 |

0.35 |

- |

- |

0.25 |

- |

- |

Bearing steel. |

| 55S7 |

- |

- |

0.55 |

- |

0.60 |

- |

- |

1.80 |

- |

- |

Spring steel. |

| 15N20 |

- |

- |

0.75 |

- |

0.4 |

- |

2 |

- |

- |

- |

Often used for damascus. |

| Z100CDV5.1 |

A2 |

1.2363 |

1.00 |

5.00 |

- |

1.10 |

- |

- |

0.20 |

- |

Strong impact strength |

| 100MCW4 |

O1 |

1.2510 |

1.00 |

0.60 |

1.10 |

- |

- |

- |

- |

0.60 |

Excellent wear resistance. |

| Z155CDV12.1 |

D2 |

1.2379 |

1.55 |

12.00 |

- |

1.00 |

- |

- |

1.00 |

- |

Corrosion resistant steel. |

Some indications for your choice...

Some indications for your choice...

Some advices to direct you:

- Gizmos, small tools, tests: XC48

- Penknives, short blades: XC75, 90MV8

- Average, or large blades if no effort: XC75, 90MV8

- Long Blades, bowies, daggers: XC75, 55S7

- Swords, machete: 55S7

This list is voluntarily limited to some oxydable

steels, not or slightly allied.

Moreover, each cutler often has his preferred steels, that he

can easily get and/or he have learned to know.

Some steels in detail...

Some steels in detail...

XC48

XC48

Chemical composition:

- Carbon from 0.45 to 0.51%

- Silicon from 0.15 to 0.35%

- Manganese from 0.4 to 0.7%

Temperature of forging: 850 to 1100°C

Temperature of annealing: 650 to 700°C

Temperature and medium of quenching: 800 to

850°C in water

Hardness after hardening: 58 HRC

Curve for tempering: See opposite.

XC75

XC75

Chemical composition:

- Carbon from 0.5 to 0.90%

- Silicon from 0.1 to 0.4%

- Manganese from 0.5 to 0.8%

Temperature of forging: 850 to 1100°C

Temperature of annealing: 700 to 720°C

Temperature and medium of quenching: 780 to

850°C inoil

Hardness after hardening: 62 to 65HRC

Curve for tempering: See opposite.

90MCV8

90MCV8

Chemical composition:

- Carbon from 0.85 to 0.95%

- Silicon from 0.1 to 0.4%

- Manganese from 1.9 to 2.1%

- Chromium from 0.2 to 0.5%

- Vanadium from 0.05 to 0.15%

Temperature of forging: 850 to 1050°C

Temperature of annealing: 680 to 720°C

Temperature and medium of quenching: 800 to

820°C in oil at 80°C

Hardness after hardening: 63 to 65HRC

Curve for tempering: See opposite.

Attention, this steel is delicate to anneal. Annealing in cold vermiculite

leaves it impossible to drill and file

(ideal to damage the tools). It is there that the old files

render service!

Make a slow annealing in the dying fire of forge.. The little rate of chromium

makes him take a light hardening if cooling is not very slow!

| | |