Blacksmithing

and Cutlery

by Gérard HEUTTE

|

|

Shaping a blade with file

Shaping a blade with file

|

Here is an effective method to make the raw grinding of

a blade with the file. This step, impossible to

circumvent, is made just after forging and annealing, before other heat treating.

The people "equipped" make this step with the backstand.

It is easier and more rapid! You can get the same quality

results by working correctly with the file!

Preparation

Preparation

Before beginning the effective part of the work with the

file, it will be necessary to carry out two operations of preparation:

> Annealing

It is used to remove the internal tensions and to prepare metal for machining (filing).

> Remove calamine. Calamine is the black layer on the

surface of steel. To avoid wearing out the files prematurely, it is

advisable to remove it. The simplest method is to plunge the

blade for one night in the white vinegar: Simple, effective,

economic!

Tools

Tools

Here are what I advise:

> Good flat file, like bastard.

> Large round file for starting the tang.

> Small round (diam 3) for the notch on the edge.

> Special tool for the ricassos. Or, instead of that,

two metal bars and two screw clamps.

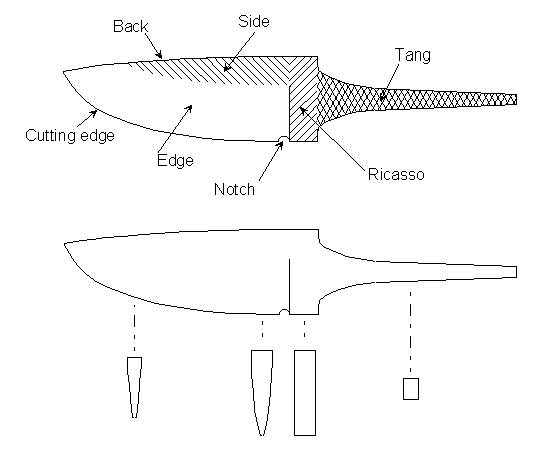

Blade form

Blade form

To avoid disappointments during assembly, here is the

form of the blade to be obtained here. The important points will

be below detailed, in the step by step explanations.

Principle

Principle

Here are the steps list which will make

possible to arrive at the result:

> Outlining. In the order: Back of the blade, edge, tang.

> Surfacing. With in the order: Ricasso, tang, sides.

> Edge

> Completions: Breaking of angles, Notch, coarse polishing.

It is necessary to avoid touching anything at anytime!

When outlining is finished, the profile of the blade is the final one.

No need to come back there. Idem for the ricasso, once at the

good thickness, no need to work on it later!

A methodical process of work is one of the keys for a good

result.

Outlining

Outlining

For all this part, you can tighten the blade in

a vice without particular precaution since the sides

have not been worked yet.

Back of blade

Begin by working on the back of blade.

Work in the length in order to avoid holes or to

leave bumps. Regularize by using the flatness of the file.

You must remove sufficiently matter to see the traces of the

file on the entirety of the back (i.e. no more forging traces).

Edge

When the back of the blade is correct, turn the blade

to work on the edge (profile), with the same method as above.

Attention to not be wounded with the tip of the blade.

Tang

The tang will require a detailed attention.

First of all, it is necessary to understand well the

desired geometry (see figure opposite).

The tang will require a detailed attention.

First of all, it is necessary to understand well the

desired geometry (see figure opposite).

It is necessary to keep at the junction ricasso-tang, a small

flat part (from 1 to 2 mm in height). It is on this surface

that the future guard (or bolster) will take support.

The clearness of the unction ricasso-tang will depend on its

quality.

> On each side of the tang, machine the flat support of the guard

(in red on the sketch). Take care of

the alignment of the two sides of the tang. You can control it

constantly with a reglet.

> Cut the round-off (in blue on the figure) which will come

tangenter the flat. It could be necessary to cut a little in

the matter of the tang.

> Form the beginning of the tang (in green on the figure)

which will tangenter the round-offs. Then continue

towards its end.

NB : At this step,

you will not modify any more the outlining or profile of the blade except for the

notch to the edge-ricasso junction (if you wish to do one of

them).

Surfacing

Surfacing

Ricasso

The ricasso will have to be worked on each side of the blade.

Its faces will have to be quite

parallel. You can use a slide caliper or a

micrometer. Use the flatness of the file to ensure a good

flatness.

If the "level" must go down a little below that of the sides or the tang,

it doesn't matter. The difference will be

corrected later.

If one wishes a "raw forging" completion, it is

necessary to start from a well forged blade and to be make only a light machining.

Tang

Each face of the tang must be worked in the

length to ensure a regular reduction thickness and a certain

flatness (not too critical). Take care not to damage

the work made on the ricasso!

During the work on the two sides, attention to the

alignment of the tang on the axis of the blade. This step allows

to correct a light misalignment by removing more material on one side than on

the other!

Sides

The machining of the sides will be done mainly

in the length to ensure a progressive reduction of the thickness of

the blade. It is necessary "to be connected" to the work

made on the ricasso with a continuous surface.

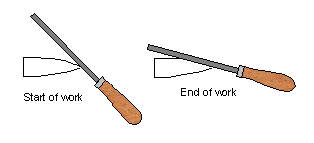

Edge

Edge

For working the edge, always start

by working with a rather large angle in order to outline a wire

centered well. Then gradually incline the file

to go up the working area towards the back of the blade and to thus

join the side. See sketch opposite.

For working the edge, always start

by working with a rather large angle in order to outline a wire

centered well. Then gradually incline the file

to go up the working area towards the back of the blade and to thus

join the side. See sketch opposite.

Mark

At the beginning, it will be preferable to trace

on the side the line who will be used as reference mark for the

Side-Edge junction. With the practice, you will be able

to do without this mark.

Ricasso-Edge Junction

It is one of the most delicate parts to make.

I strongly recommend the use of a specialized tool: the

ricasso screw

clamp.

Instead of that, you can replace this tool by two metal

flat parts maintained by screw clamps.

Support the smooth edge of the file against the ricasso screw clamp

begin the edge by strongly inclining the file (45°).

Work alternatively on the two sides of the

blade. It is necessary to arrive at the thickness desired for

the wire and to center this wire compared to the ricasso.

For questions of decarburization and mechanical resistance at

the time of hardening, it is necessary to leave a thickness on the edge.

In general, I leave a thickness of 0.5mm for the short

blades and 1 mm for the long blades.

Once the edge with the good thickness and well centered, you can

incline the file to refine the edge and to go up until the

mark.

The rest of the edge

For the remainder of the edge, proceed

in a similar way. Try to also work in the

length to have straight edge.

Completions

Completions

Breaking of angle

With a fine and soft file, remove all

the burs and break all the too sharp angles.

Notch

It is now the moment to cut the notch at the

edge-ricaso junction. Use for that a small round file. Do not dig too

deep. It is just necessary to separate the edge from the ricasso

to facilitate sharpening.

Tang

If needed, for example for a caulking at the end

of handle, round the tang towards its end. Start by

making a chamfer at 45° on the four edges to form a quite regular

octagonal section. Then round the octagone obtained.

Polishing

Before passing to heat treating, make a coarse polishing.

I use for this operation an

abrasive disc of 120 grit assembled at the end of drilling machine.

Result

Result

Here is a blade ready for the heat treating.

The ricasso and the sides were left "raw forged".

The surface quality of the edge is that of sandpapering with the

disc of 120 grit. The tang was not polished.

Here is a blade ready for the heat treating.

The ricasso and the sides were left "raw forged".

The surface quality of the edge is that of sandpapering with the

disc of 120 grit. The tang was not polished.

| | |