Blacksmithing

and Cutlery

by Gérard HEUTTE

|

|

Forge a Piedmontese blade

Forge a Piedmontese blade

|

The "Piedmontese" is a model of folding knife simple to

realize (with a little of method), robust and practical at use.

For the practical and comfort aspects, I prefer the

models having of a lens or a pallet where the thumb can rest easily and

comfortably. This tutorial presents a possibility to produce

this pallet. Except the realization of the pallet, a blade of

Piedmontese does not present a particular difficulty.

Here, I make first the pallet then the blade. But, it

is completely possible to make the opposite. It is only a

question of personal liking.

Flat part

Flat part

It is first of all necessary to make a flat part of

adequate size. Attention, with the method suggested here, you

should not have a too low thickness at the risk of

encountering difficulties to make the

pallet! Keep a thickness of approximately 4 mm. If a finer

blade is wished, you can always decrease the

thickness after having made the pallet.

A width from 20 to 22 mm and a thickness from 4 to 5 mm are a

good base.

the section of origin (of C70 from "Acierie du Tarn" in 20x10)

|

|

The flat part obtained

|

Pallet

Pallet

This is the delicate part! It is necessary to

create a shoulder at the end of the flat part. If the thickness

is too low, you can create a fold instead of driving back the metal.

Pposition the flat part on the edge and resting against an

angle of the anvil. Flatten delicately. Correct the

least defect (twist, torsion, shift) as soon as it appears. Take care

to work quite hot (orange) because of the important

deformations of the metal. Forge on the edge regularly to

form a round or rectangular pallet.

The beginning.

|

|

The pallet starts to be formed.

|

The pallet is gently corrected.

|

|

If needed, idem for the flat part

|

The blade outline seen from profile...

|

|

and from the top.

|

Drawing out

Drawing out

Now, it is necessary to finish the blade without

damaging the pallet!

Now, it is necessary to finish the blade without

damaging the pallet!

Draw out the metal to form a longer flat part.

It is now that you must act if a finer blade is

wished.

Blade

Blade

The rest of the blade does not present any

particular difficulty! I will illustrate the continuation by a

few phots. The bases are detailed in the tutorial to learn to

forge a blade .

Small practical trick: Do not on to the blade. You will be

able to always make this operation at the end. In fact, I place

it systematically on one side!

Small practical trick: Do not on to the blade. You will be

able to always make this operation at the end. In fact, I place

it systematically on one side!

Then, cut the flat part to detach the blade. The

cut is done approximately at 60°. Bevel is made on the wrong way

i.e. the point diametrically opposed to the pallet. See sketch

opposite.

As the cut puts the tip at the bottom, it is now necessary to

"raise" the point.

A bit after the cut

|

|

The point went up

|

Working and completion

Working and completion

The blade is now shaped:

> Rectification of outline if needed.

> Creation of the edge.

Note: On this example, I have a bit "failed" the cut by

leaving too much matter! At the end, I have a blade which

makes 130 mm length. While making the edge, the blade would

have still lengthened by 10 to 15mm! I thus stopped the job

here. The blade edge will be finished with the file...

> Planing.

> Coarse completion with the file.

Here is the blade after the outline with the file. The

"small defects" were removed. The pallet was regularized.

Some particular points to check:

> The two faces of the blade around the (future) pivot must be

plane and parallel.

> The thickness of the blade must be maximum around

the (future) pivot.

And afterwards?

And afterwards?

And afterwards, it is the great classic:

> Annealing

> Completion

> Drilling axis hole (see below)

> Normalizations

> Hardening

> Tempering

> Polishing

Then, it is time to switch to another tutorial:

Assembly of a Piedmontese folding knife .

Drilling

Drilling

The hole intended to

be the pivot is usualy drilled after annealing and basic completion...

With the major question: Where to drill?

Here is how I proceed:

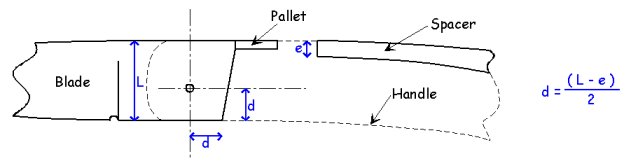

(1) Choose the width of the spacer (e). In general, count 4 or 5 mm.

(2) I subtract (e) from the width of the blade (L), then I divide the result

by 2 to determine the distance (d).

(3) I position the pivot at the distance (d) from the bottom and the back of

the blade.

With a sketch, it is much simpler:

| | |