Blacksmithing

and Cutlery

by Gérard HEUTTE

|

|

General points about heat treating

General points about heat treating

|

Heat treating is essential to make a good blade! This page presents some information

to be known before seeing in detail the main heat treatments.

Bases

Bases

The term "Heat treatment" indicates operations

of heating and cooling, controlled in time, in order to give to steel

properties adapted to the future use.

The heat treating acts on the macroscopic structure and

the mechanical state of steel, without modifying its composition.

The traditional and artisanal metallurgy calls mainly upon

continuous cooling. The modern metallurgy techniques use more and more

isothermal treatments.

Temperature and color

Temperature and color

For heating, the observation of steel color

remains a good indicator. To make this method

reliable, it is necessary to observe steel in the half-light.

It should however be noted that the interpretation of the

colors may vary from one individual to another!

The table below is thus given as an indication...

Since antiquity, generations of blacksmiths have

made remarkable objects with these bench marks!

| Temperature |

Color |

Example |

| 550°C / 1022°F |

Brown |

|

| 660°C / 1220°F |

Dark red |

|

| 780°C / 1436°F |

Red |

|

| 860°C / 1580°F |

Red Orange |

|

| 930°C / 1706°F |

Orange |

|

| 990°C / 1814°F |

Orange Clear |

|

| 1050°C / 1922°F |

Yellow |

|

| 1200°C / 2192°F |

White |

|

Curie temperature and loss of magnetism

Curie temperature and loss of magnetism

The Curie temperature is the temperature above which steel becomes paramagnetic (i.e. the part

will not be attracted by a magnet). The matter is in disorder state in terms of magnetic spin

(not atomic structure). This temperature is 770°C

for steel. This loss of magnetism is reversible when the temperature goes back below the Curie

temperature.

This physical property is a good point of reference. For non-allied steel with a carbon content

higher than 0.65%, the Curie temperature can be used to determine hardening temperature (usually

just above Curie temperature). Below

0.65% or for allied steels, the hardening temperature is higher. For allied steel or non allied

steels with a carbon content less than 0.65%, the Curie temperature will be a good basis,

but the part must be heated again to reach a higher temperature. Here, the experience will

be useful.

For practical aspect, a powerful magnet is chosen. Small attractions should also be detected.

Personally, I suspend my magnet at the end of a string around the forge. Approaching the part,

I can check the loss of magnetism quite fine, observing the deviations of the magnet. I have

thus increased sensitivity compared to a magnet held in the hand while avoiding thermal

radiation! For intense use, think cool the magnet occasionally with a little cold water.

Put again the part into the to fire for a few moments before hardening.

Thermal cycles

Thermal cycles

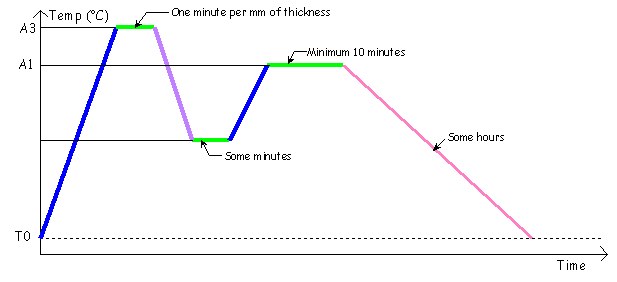

The heat treatments are made via thermal cycles.

A thermal cycle is a combination of the temperature and

time factors. In other words, it is a temperature curve according to

time.

In detail of the heat treatments, I provided typical cycles.

In order to facilitate interpretation of them, I use the

following notations:

> Blue line: Moderated heating, typically in a forge fire or a gas forge.

> Green line: Stage, keep at constant

temperature.

> Pink line: Very slow cooling, typically in

vermiculite, sand, or ash.

> Purple line: Moderated cooling, typically in the

air.

> Red line: Fast cooling, typically in water, oil or

goop.

Here is a thermal example of cycle (absolutely eccentric!) :

Heat treatments

Heat treatments

The heat treatments used in cutlery are successively:

> Annealing which

is used to remove the internal stresses.

> Normalization

to refine steel grain.

> Hardening which

hardens steel, but makes it fragile.

> Tempering which

removes much brittleness due to hardening at the detriment of a bit of hardness.

| | |